Projects

Bolt Pulling Tool

Tool used for retracting hinge bolts on Åsgard Gas Compresion template roof panels.

Crack Delimiting Drilling Tool

Customer: DeepOcean AS / Talisman

Project description:

Developing, producing and testing of the tool for repair work on Varg platform jacket.

Pipe OD - 1m

Drill hole size - 70mm

The CDD tool was used during a subsea operation in the summer of 2011 with a great success.

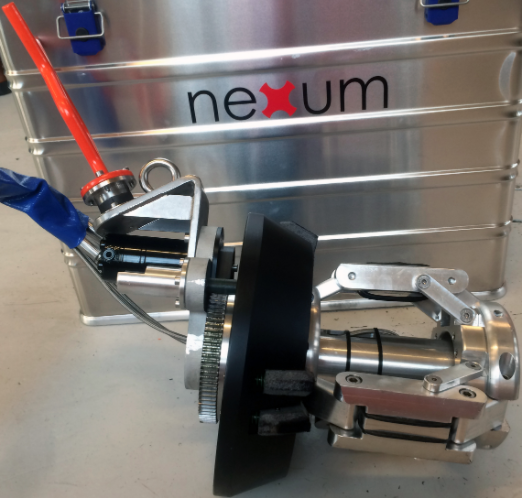

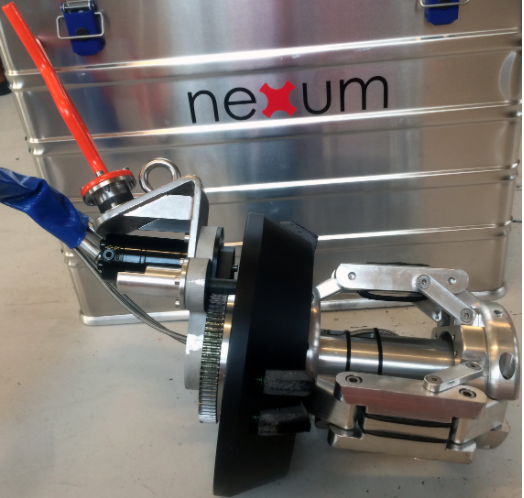

Hub Cleaning Tool

Nexum Engineering has just finished a project on engineering, fabrication, assembling and testing of a Hub Cleaning tool for Statoil.

Customer: Statoil ASA

Project description: Engineering, fabrication, assembling and testing of a Hub Cleaning tool. The tool can be used on both inboard and outboard ends of a pipeline and is installed by inserting it into a pipe bore and activating the "gripper" mechanism. The hydraulic motor then rotates the brushes to clean the sealing surfaces of the hub.

The Cleaning tool is very light and compact and is only 0,5 meters long. The length of the tool was the main design challange in this project.

Refurbishment Icarus PLET Tie-in System

Customer: Statoil Petroleum AS

Project description: Nexum Engineering AS was awarded a contract from Statoil Petroleum AS for refurbishment of one Icarus PLET tie-in system on Åsgard S-101. This project required a full refurbishment and testing of the Icarus PLET. The work took place in our new workshop located in Orstad, Klepp, with great success.

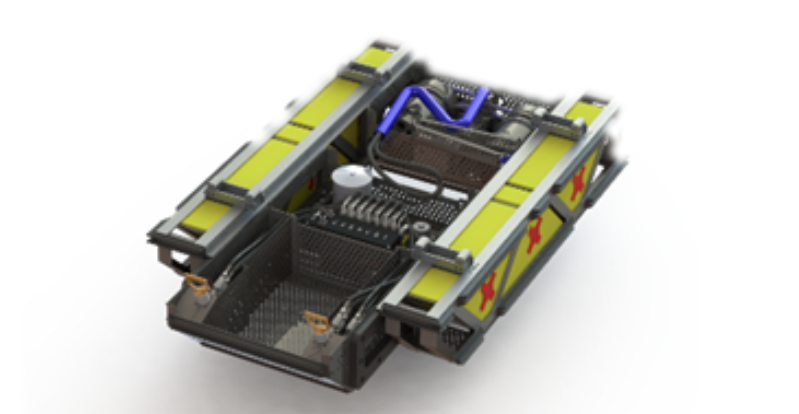

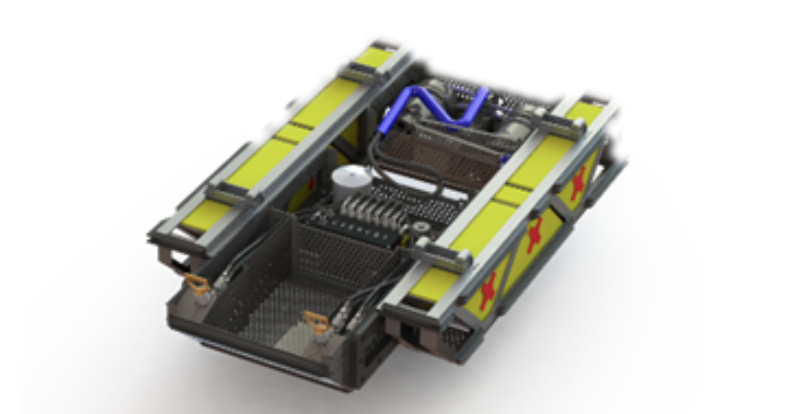

ROV Basket System

Customer: Innova/ Technip

Project description:

Nexum delivered a ROV basket design for the Åsgard Gas Compression project.

Integrated systems:

Hydraulic control system for module handling

Heating unit

Additional system:

Fluid Transfer Unit.

Standard interface for drawer

Adaptable to all type of work ROV’s

Module based design

Easy connection to ROV

Existing tooling can be built in this system

Reduced ROV down time

Reduces cost

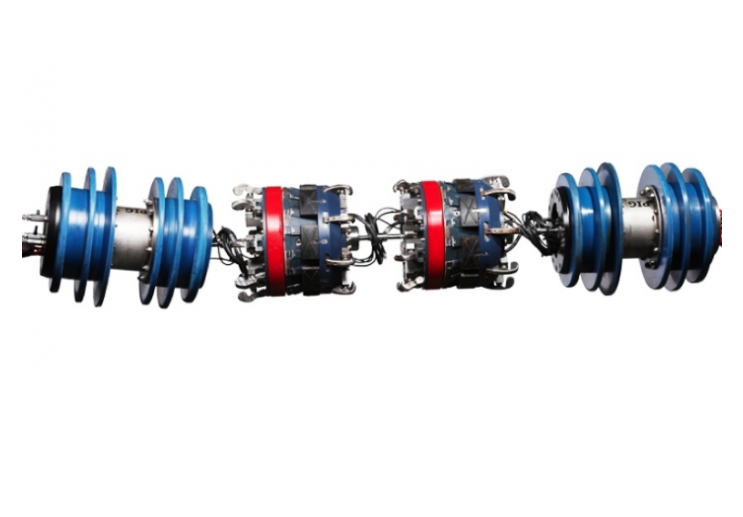

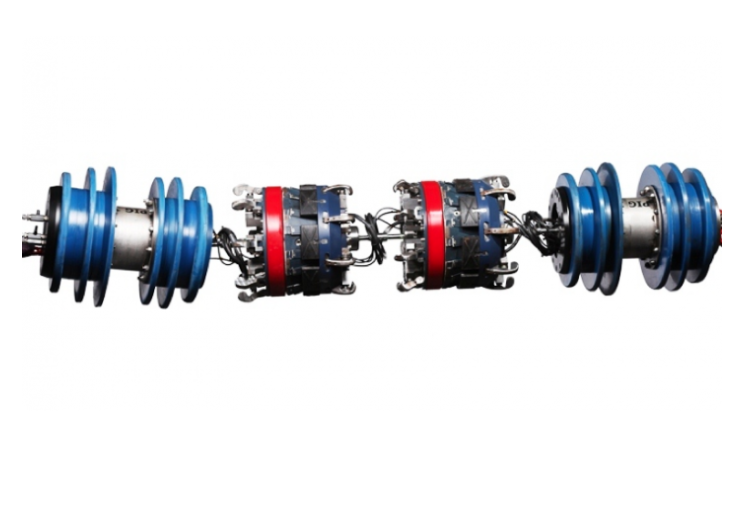

Tethered Piggable Plug

Customer: IK Stavanger AS

Project description:

Head the testing and qualification of a tethered piggable plug for a concrete line pipeline.

Pipe ID: 410-440mm

Bend Radius: 1.5D

Isolation pressure: 8 bar

Umbilical End Cap

Four Umbilical End Caps were designed for our client to seal cut umbilical ends. Caps are lightweight, easy to assemble and operate. Extrusion gap of these caps allows to seal round objects (pipes, umbilicals etc.) with OD range Ø195 – 201 mm.

Design life: 20 years.

12 MM High Pressure Plug

Development and qualification of a plug for sealing of a hole in a water injection valve.

Customer: DeepOcean /Statoil

Project description: Developing a 12 mm plug to withstand 280 bar for sealing a hole in an injection valve.

Tested up to 450 bar.

Completed a successful FAT.

Ref. FFU magazine, DYP-article about the project.

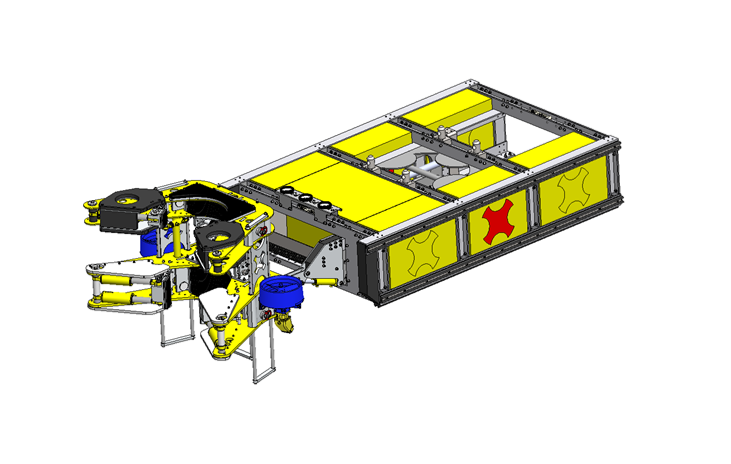

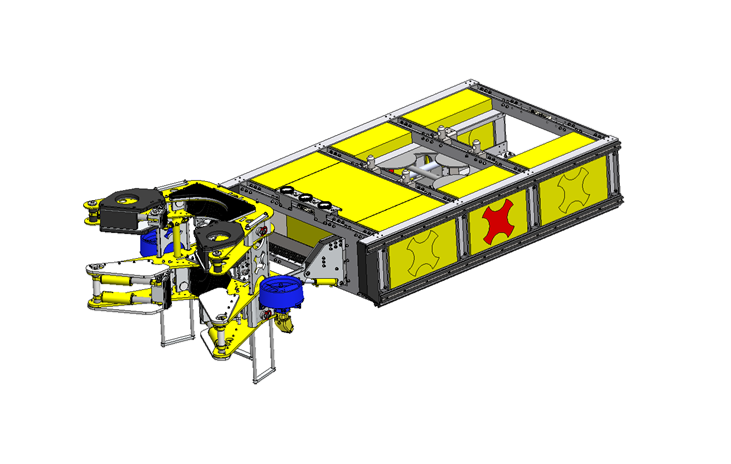

Riser Wear Protection Running Tool

Running tool for installation of wear protectors in J tubes and on subsea chute. Project included all additional tools for handling and installation of wear protectors Running tool is mounted on Nexum ROV Belly basket.